Jacking Equipment

Jacking Beams, Pit Jacks, Trolley Jacks, Transmission Jacks and Engine Cranes.

Vehicle Jacking Equipment

Auto Workshop Equipment Services Ltd offer a comprehensive range of Jacking Equipment including Jacking Beams, Pit Jacks, Trolley Jacks, Transmission Jacks and Engine Cranes.

If you cannot find the jacking equipment you are looking for on our site, or you have any questions relating to any of our products, please contact us and we will be happy to assist you.

Vehicle Lift Jacking Beams

2 - 6 Tonne

Rated up to 6 Tonnes, Majorlift vehicle lift jacking beams are trusted by thousands of garages as well as the UK’s leading roadside recovery service

Model Options

- MPJ2 2-tonne air-operated

- HPJ2 2-tonne hand-operated

- MPJ2.8 2.8-tonne air-operated

- HPJ2.8 2.8-tonne hand-operated

- MPJ4 4-tonne air-operated

- HPJ4 4-tonne hand-operated

- MPJ6 6-tonne air-operated

Main Features

- Top Beam – 0ur 2 and 2.8 tonne models now with an extra-wide extending top beam to 1700mm.

- Ram and Scissors – A full 260mm (10.25”) lift with proven hydraulics, the heart of every Majorlift jacking beam: gutsy, robust and very reliable.

- Safety Features – Hose burst valve, pressure release valve prevents overloading, finger guard complies with European machinery directive and CE marking.

- Quietest Ever Majorlift Pump – The new quieter design of Majorlift pump, built into every air jack – significantly enhances performance and reduces noise as well as further improving operational reliability.

- Three-Position Mechanical Lock – Engages automatically creating safe working platform when carrying out extensive wheel overhauls.

- Raiser Blocks – Supplied as standard with each beam. Rubber-topped screw pad 1532A and aluminium block 1526 that will fit anywhere over the length of the beam. Additional blocks can be supplied as optional extras.

- Support Arms – Easy roll operation from quality roller bearings – minimum effort, easy movement.

- Roller Hook or Roller Flat Support Arms Supplied As Standard – Majorlift also fit support-arms (extra P.O.A) to accommodate most makes of lift including Bradbury, Tecalemit, Werther, Stertil-Koni, Stenhoj, Laycock, Hofmann, Istobal, Fogg, Ravaglioli, Nussbaum, Consul, Rotary, Maha, Autec, Sun, Cascos, Omer, Texo and Wheeltronics.

Included

- 3 years warranty as standard

- Delivered to site

From £POA + VAT

5 Year Lease Price From £POA + VAT per week

.png)

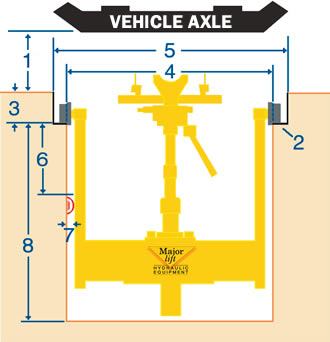

Pit Mounted Commercial Jacks

Rated up to 40 Tonnes

Rapid, reliable and rigorously safe – the Pit Mounted Commercial Jacks will tackle anything and everything up to 40 tonnes

Model Options

- MPJ12 – 12t twin ram air-operated pump

- MPJ20 – 20t twin ram air-operated pump

- HPJ12 -12t twin ram hand-operated pump

- HPJ20 – 20t twin ram hand-operated pump

- MPJ40 40t twin ram air-operated pump

- MPJ13 – 13t twin ram air-operated pump

- HPJ13 – 13t twin ram hand-operated pump

Main Features

- Twin ram operation – Greater operational stability, efficiency and safety. The rams slide transversely, making precise positioning under the vehicle possible, AND they can be used independently or in tandem, allowing one or both sides of the vehicle to be lifted.

- Surface Engineered for a longer, harder working life – All key components in a Majorlift jack now have their working life greatly extended through a patented surface engineering process. This range of treatments develop iron nitride surface compound layers to toughen the surface and resist rust. The nitrogen-enriched zone can improve yield and fatigue strengths by as much as three or fourfold.

- Control valves as standard – Precise lowering for optimum safety and working conditions.

- Pressure relief valve – Automatically prevents overloading.

- Positive mechanical safety lock – Threaded rams and collars greatly enhance operator safety especially against accidental lowering.

- Pumps can be either air-powered or hand-operated – Air-operated gives easy and rapid lift; hand gives easy double action pumping.

- Quietest Ever Majorlift Pump – The new quieter design of Majorlift pump, built into every air jack – significantly enhances performance and reduces noise as well as further improving operational reliability.

- Load bearing supports and spring loaded rollers – A long established Majorlift design for smooth, easy and safe movement along the pit.

- For lifting loaded tri-axle trailers, the 20-tonne model must be used.

- Custom-built beams for unusually shaped pits.

- Test certificates supplied with all beams.

Included

- 3 years warranty as standard

- Delivered to site

From £POA + VAT

5 Year Lease Price From £POA + VAT per week

Lift Mounted Commercial Jacks

Rated 8 to 20 Tonnes

The Majorlift Lift Mounted Commercial Jacks have proven to be a powerful combination to provide reliable operations.

Main Features

- Twin ram operation – Greater operational stability, efficiency and safety. The rams slide transversely, making precise positioning under the vehicle possible, AND they can be used independently or in tandem, allowing one or both sides of the vehicle to be lifted.

- Surface Engineered for a longer, harder working life – All key components in a Majorlift jack now have their working life greatly extended through a patented surface engineering process. This range of treatments develop iron nitride surface compound layers to toughen the surface and resist rust. The nitrogen-enriched zone can improve yield and fatigue strengths by as much as three or fourfold.

- Positive mechanical safety lock – Threaded rams & collars greatly enhance operator safety especially against accidental lowering.

- Control valves as standard – Precise lowering for optimum safety and working conditions.

- Pressure relief valve – Automatically prevents overloading.

- Load bearing supports and spring loaded rollers – A long established majorlift design for smooth, easy and safe movement along the lift.

- Quietest Ever Majorlift Pump – The new quieter design of Majorlift pump, built into every air jack – significantly enhances performance and reduces noise as well as further improving operational reliability.

- Sliding frame design – Majorlift have designed a sliding frame beam with adjustable width for use on lifts with adjustable platforms, this allows servicing of vehicles with different tracks to be accommodated on the same lift.

- Lift Suitability – The flexibility of design of the 8 to 20 tonne range ensures that we can provide a suitable jacking beam without any performance or safety compromises to fit ANY make of fourpost or scissor commercial lift, including: Bradbury, Tecalemit, Stertil-Koni, Stenhoj, Laycock, Hofmann, Istobal, Fog, Ravaglioli, Nussbaum, Consul, Rotary and Maha.

- Test certificates supplied with all beams.

Included

- 3 years warranty as standard

- Delivered to site

From £POA + VAT

5 Year Lease Price From £POA + VAT per week

Vertical Transmission Jacks

Rated at 1000KG OR 2000KG

Rated at either 1000 kg or 2000 kg, this unit is designed specifically to provide safe, rapid removal and replacement of heavy transmissions.

Vertical Transmission Jack VTJ1000

Simple and safe to use by just one mechanic, the unit’s low minimum height (1155mm) and unusually high extended height (2100mm) increase the unit’s flexibility. Stability comes from its wide base, safely spread over four legs. N.B. Transmission Jack Adaptor Plate is not included in the standard price.

Vertical Transmission Jack VTJ2000

Provides 2 tonnes of lifting capacity. Specially designed to assist the removal of gearboxes and transmission parts safely by 1 technician. Low minimum height: 1110mm. Extended height: 2130mm

Pit Transmission Jack VTJ1000P

A pit version of our Vertical Transmission Jack. Wheels are situated at each corner of a rectangular base rather than diagonally otherwise specification is as VTJ1000. This gives increased stability when running along a pit floor and is suitable for pits of 800mm minimum width.

Main Features

- Two way tilt adaptor – The lifting adaptor can easily be adjusted into a precise position when removing most types of transmission.

- Triple extension ram with chrome piston – Provides up to 945mm of stroke.

- Manual hydraulic double acting power pack – Proven on other Majorlift equipment, this allows units of up to 1000kg to be removed with a smooth, safe and highly controllable application of power.

- Load test certificate – supplied with each unit.

- CE markings – conform to EC directives.

Included

- 3 years warranty as standard

- Delivered to site

From £POA + VAT

5 Year Lease Price From £POA + VAT per week

Pit Transmission Jack

Rated Upto 1000KG

Roll along, remove, roll back, replace. There is, quite simply, no easier, safer and quicker way to remove gearboxes, diffs and propshafts than the PTJ1000.

Rated up to 1000kg, it can be custom built to suit your pit, and to tilt, turn and manoeuvre heavy transmissions to pin-point accuracy. N.B. Transmission Jack Adaptor Plate shown is an optional accessory.

Main Features

- Two way tilt adaptor – The lifting adaptor can easily be adjusted into a precise position when removing most types of transmission.

- Hose burst valve fitted – Safety valve fitted to prevent accidental lowering in the unlikely event of hydraulic pressure loss.

- Triple extension ram with chrome piston – Provides up to 945mm of stroke.

- Rollers, fitted with needle bearings – Smooth, virtually effortless running along the pit rails – even when load bearing.

- Manual hydraulic double acting power pack – Proven on other Majorlift equipment, this allows units of up to 1000kg to be removed with a smooth, safe and highly controllable application of power.

- Load test certificate – supplied with each unit.

- CE markings – conform to EC directives.

- Capacity 1000kg.

Included

- 3 years warranty as standard

- Delivered to site

From £POA + VAT

5 Year Lease Price From £POA + VAT per week

Floor Transmission Jack

Low Clearance Floor Transmission Jack – FTJ1000

If your operations ever call for a low clearance floor transmission jack, the FTJ1000 has all the qualities you expect from a Majorlift product which, since its introduction in 2001, has constantly been updated and enhanced.

It is hugely popular in garages where there is no available pit, or where there is a low roof clearance.

Robust, reliable and simplicity itself to use, the Floor Transmission Jack built-in design features allow you to position accurately, and it is particularly well suited to the removal and fitting of transmissions.

Main Features

- Easy access pump handle – Turning through a complete 360 degree arc, and operable by just one mechanic, makes height adjustment on the FTJ1000 simple.

- Two way tilt facility – The adjustable lifting head tilts through a 70 degree arc, enabling precise positioning and safe manoeuvrability by just one operator when removing and fitting most types of transmission.

- Heavyweight power lifting – The unit will support a weight of 1 tonne on any of the four load points.

- Heavy duty wheels – The large diameter wheels spread the load over a wide area, making manoeuvrability of the jack easy – even when supporting a heavy weight or when transporting loads over uneven surfaces

Included

- 3 years warranty as standard

- Delivered to site

From £POA + VAT

5 Year Lease Price From £POA + VAT per week

Distributors for